Close

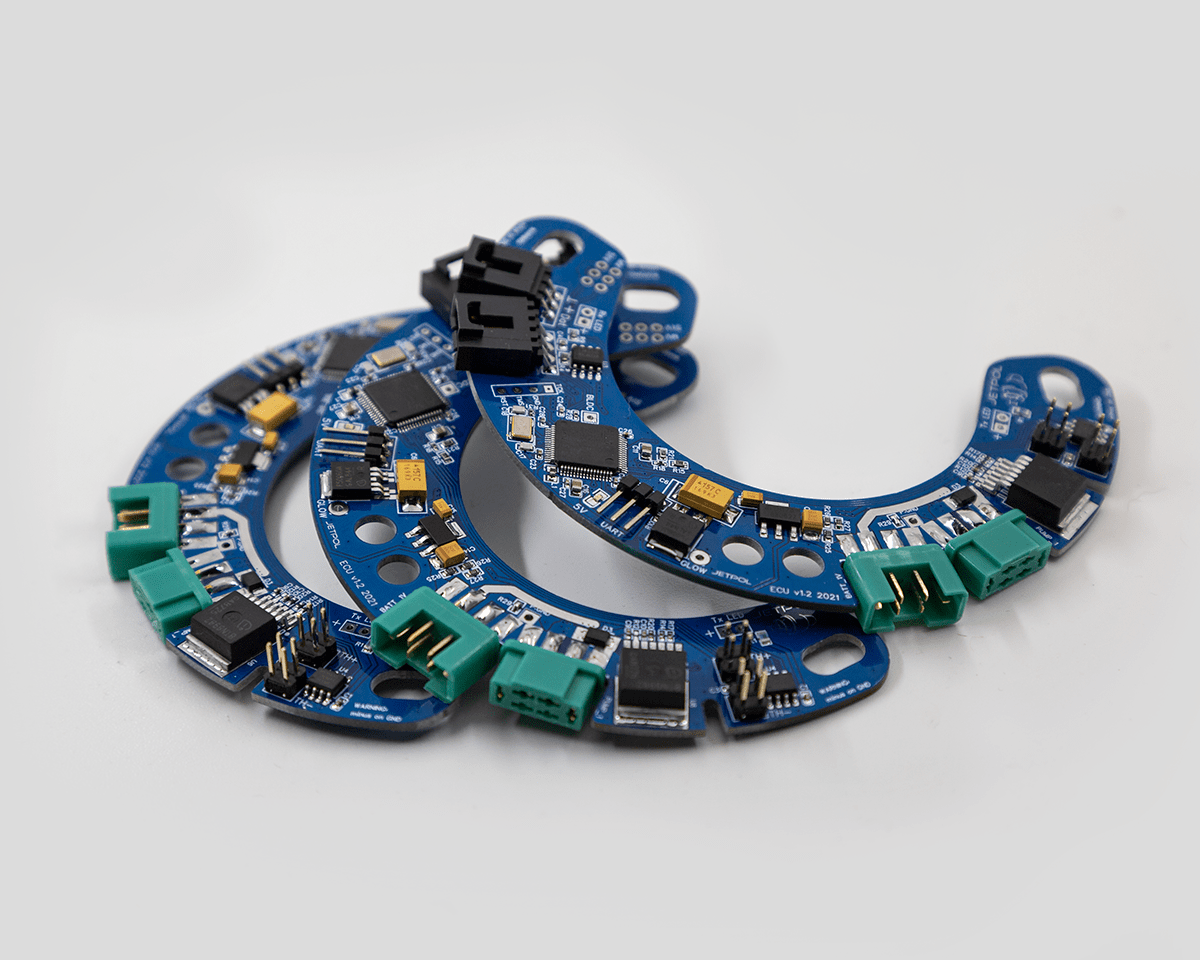

The module was designed as a single-board microprocessor system based on a 32-bit microcontroller with the Arm Cortex core. It is made in SMD technology. As part of the implementation of the assumption of maximum flexibility, mechanisms are introduced to adapt to various electrical requirements of cooperating elements – valves, pump, starter, power source.

Our control module for turbine micromotors of the GTM series and similar has been designed as a single-board microprocessor system based on a 32-bit microcontroller with an Arm Cortex core. It is made in SMD technology. Its dimensions and shape enable installation directly on the engine, under the compressor inlet cover. As part of the implementation of the assumption of maximum flexibility, mechanisms are introduced to adapt to various electrical requirements of cooperating elements – valves, pump, starter, power source. The extensive menu provides the ability to set parameters and save them in any three sets, except for the factory one, programmed in the production process. A large number of available parameters ensures full control over each stage of the turbine’s operation. The extensive user interface provides up-to-date information on the operating status of the turbine and all historical data from previous work cycles.

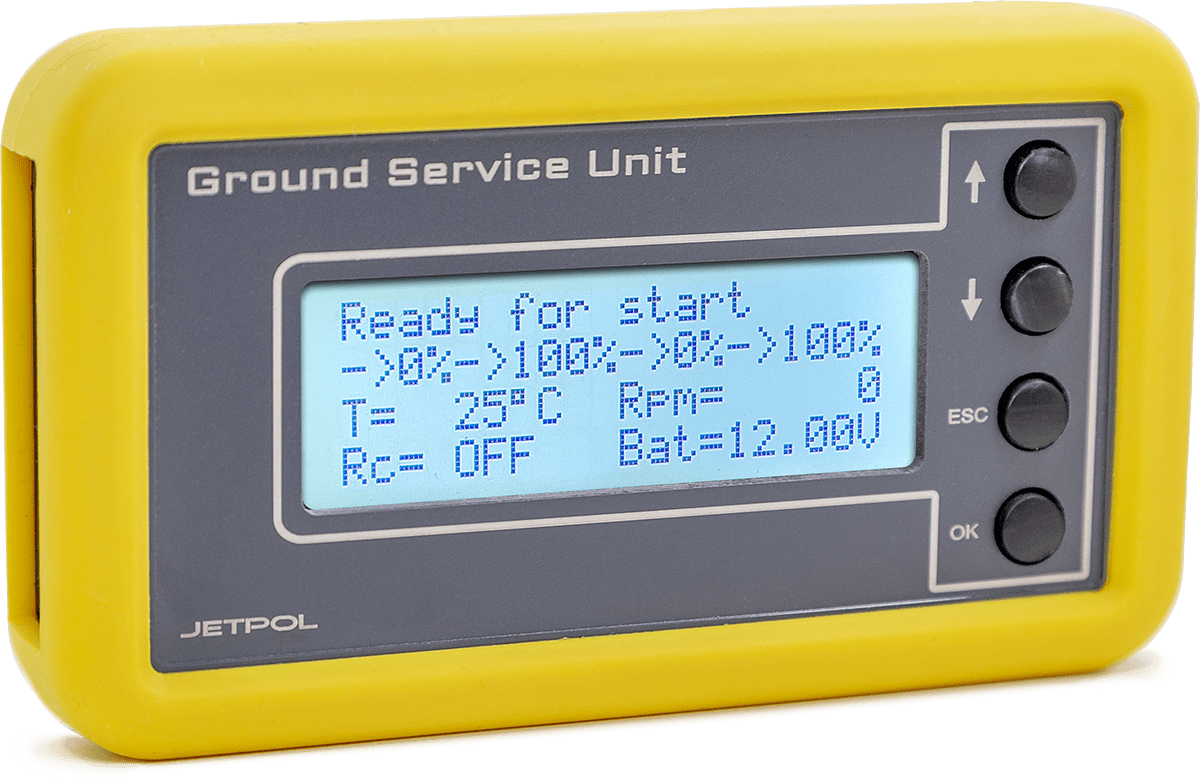

The system has two interfaces for external communication. One of them is used to connect the GSU interface with an LCD display and a small basic information module with LED diodes and an acoustic signaling device. It also has a button that activates the fuel pump and opens the main valve. The second interface is used for bi-directional communication with the bluetooth module or transmission of measurement data via the RS232 serial port. Bluetooth communication ensures cooperation with the application installed on mobile devices, which is used to modify the parameters and read the current operating status of the turbine.

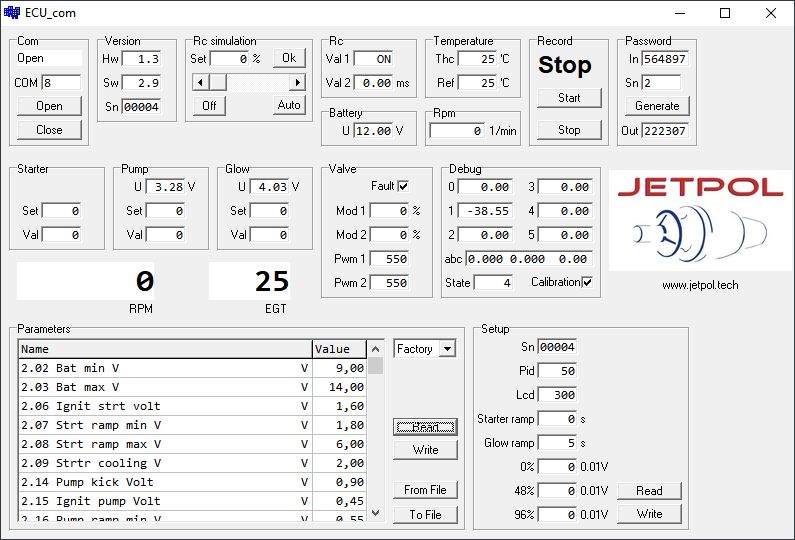

To ensure maximum protection of the turbine engine and all aspects of operational safety, advanced algorithms for controlling operating parameters have been applied. This applies to exceedances and the lack of implementation of the given stages. All emergency events are saved in the non-volatile memory for later analysis. For service purposes, dedicated software (optional) is used, cooperating with the control module via a bidirectional serial transmission interface (photo 1). The collected measurement data, after being visualized in a graphic form, provide full information about the operation of the turbine (photo 2).