Close

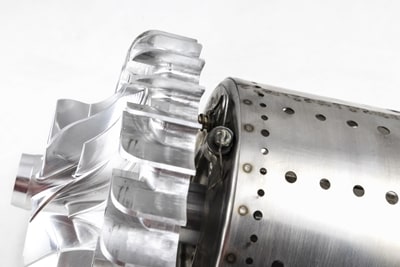

140N static thrust engine with or without equipment. Automatic start on liquid fuel (internal "kerostart"). Three-phase BLDC starter (introduced in March 2020 - it is possible to upgrade previous models). Thermal protection of the turbine bearing by using an aluminum-steel shaft sleeve. The latest bearing lubrication system with directional air flow. A mounting clamp is supplied with the engine. The equipped version has a microprocessor control and monitoring module, an interface for programming and reading parameters, a fuel pump, starting and main fuel solenoid valves, electrical and fuel cables. The product is intended for modeling applications. Requires careful reading of the instructions for safe use. If handled incorrectly, it may pose a serious threat to health and life.

160N static thrust engine with or without equipment. Automatic start on liquid fuel (internal "kerostart"). Three-phase BLDC starter (introduced in March 2020 - it is possible to upgrade previous models). Thermal protection of the turbine bearing by using an aluminum-steel shaft sleeve. The latest bearing lubrication system with directional air flow. A mounting clamp is supplied with the engine. The equipped version has a microprocessor control and monitoring module, an interface for programming and reading parameters, a fuel pump, starting and main fuel solenoid valves, electrical and fuel cables. The product is intended for modeling applications. Requires careful reading of the instructions for safe use. If handled incorrectly, it may pose a serious threat to health and life.

180N static thrust engine with or without equipment. Automatic start on liquid fuel (internal "kerostart"). Three-phase BLDC starter (introduced in March 2020 - it is possible to upgrade previous models). Thermal protection of the turbine bearing by using an aluminum-steel shaft sleeve. The latest bearing lubrication system with directional air flow. A mounting clamp is supplied with the engine. The equipped version has a microprocessor control and monitoring module, an interface for programming and reading parameters, a fuel pump, starting and main fuel solenoid valves, electrical and fuel cables. The product is intended for modeling applications. Requires careful reading of the instructions for safe use. If handled incorrectly, it may pose a serious threat to health and life.